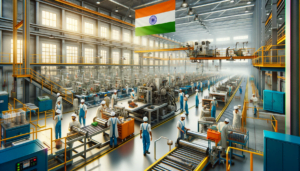

India, with its rich history and diverse culture, has emerged as a global manufacturing hub in recent years. The country offers a unique blend of traditional craftsmanship and modern technology, making it an attractive destination for businesses looking to expand their manufacturing operations.

In this article, we’ll delve into the key aspects you need to know about manufacturing in India.

Let’s begin with –

Has India become a manufacturing hub?

In the vast tapestry of global commerce, India has been quietly weaving a narrative of transformation. What was once predominantly known for its rich history and diverse culture is now emerging as a noteworthy player in global manufacturing.

India’s historical narrative is interwoven with tales of craftsmanship and trade that date back centuries. From intricate textiles to spices that traversed oceans, the country has long been a hub for the production and exchange of goods. However, the contemporary shift towards manufacturing excellence is a more recent chapter.

The Make in India Initiative:

A pivotal moment in India’s manufacturing story is the inception of the “Make in India” initiative. Launched by the government, this ambitious program aimed to transform India into a global manufacturing powerhouse. The initiative focuses on easing regulatory processes, promoting innovation, and creating an environment conducive to both domestic and foreign investments. We will discuss this in more detail later.

Diverse Industries Taking the Lead:

India’s journey towards becoming a manufacturing hub encompasses a diverse array of industries. The automotive sector has evolved, with India emerging as a manufacturing base for global carmakers. Pharmaceuticals, too, have seen a surge, positioning India as a major player in the production of generic drugs. The electronics industry, propelled by the digital revolution, has witnessed significant growth. One of India’s unique strengths lies in its ability to blend traditional craftsmanship with modern technology. From handwoven textiles to intricate jewelry, the country offers a distinct advantage in producing goods that carry a touch of heritage while meeting contemporary demands.

As we look ahead, the future of India as a manufacturing hub seems promising. Continued government initiatives, advancements in technology, and a commitment to sustainability are poised to propel India further onto the global manufacturing stage.

How is the manufacturing sector in India as of 2023?

As the curtain rises on 2023, the impact of the “Make in India” initiative is palpable. The government’s commitment to transforming India into a manufacturing powerhouse is reflected in ongoing efforts to streamline processes, reduce red tape, and offer attractive incentives. These initiatives not only fuel domestic growth but also position India as an attractive destination for international investments.

The echoes of infrastructure development resonate across the manufacturing landscape. Upgrades in transportation networks, logistics, and power supply contribute to a more robust ecosystem for businesses. Improved connectivity is not just reducing production costs but also shortening lead times, and enhancing efficiency.

International partnerships continue to play a pivotal role in shaping the manufacturing narrative. Collaborations between Indian and foreign entities facilitate technology transfer, market access, and knowledge exchange. Foreign Direct Investment (FDI) inflows remain a key indicator of the global community’s confidence in India’s manufacturing potential.

What are the top products manufactured in India for e-commerce sellers?

1. Textiles and Apparel:

The textiles and apparel industry in India is a crucial sector for eCommerce. The country has a rich tradition of textile manufacturing, producing a wide range of fabrics, garments, and home textiles.

eCommerce sellers can leverage the diversity of products available in this sector, including traditional and contemporary clothing, to cater to a broad customer base.

2. Electronics and Consumer Goods:

The electronics manufacturing sector in India has seen significant growth, driven by the demand for smartphones, consumer electronics, and accessories. With the government’s emphasis on initiatives like “Make in India” and the production-linked incentive (PLI) schemes, the electronics industry has become increasingly relevant for eCommerce sellers offering a variety of gadgets, electronics, and related accessories.

3. Home and Kitchen Appliances:

The home and kitchen appliances sector encompasses the production of a wide range of products, including kitchenware, home appliances, and furniture. eCommerce sellers can tap into the demand for products such as small kitchen appliances, cookware, furniture, and home decor items.

The availability of a diverse range of products within this category makes it attractive for eCommerce platforms.

4. Health and Wellness Products:

The health and wellness industry, including the manufacturing of pharmaceuticals, dietary supplements, and personal care products, is another significant area for eCommerce sellers.

The production of herbal and organic products, in particular, has gained traction, aligning with the growing consumer focus on health and wellness.

What is the cost of manufacturing in India as compared to other Asian countries?

Manufacturing costs in India, when compared to other countries in Asia, often provide a competitive advantage for businesses. India boasts a substantial pool of skilled and semi-skilled labor, contributing to relatively lower labor costs.

While the country has made strides in infrastructure development, certain regions may face challenges, impacting overall costs. The regulatory environment, although evolving, can still be complex in some cases. However, efforts like the “Make in India” initiative aim to simplify processes and attract investments. Raw material costs vary by industry, and India has access to a diverse range of materials.

Exchange rates, influenced by currency dynamics, also play a role in the cost structure. China, historically known for low-cost manufacturing, has seen rising labor costs, making some regions in India increasingly competitive. Vietnam, with its lower labor costs and a proactive approach to regulatory simplification, has emerged as a compelling alternative.

The overall cost dynamics depend on various factors, and businesses should conduct detailed analyses based on industry specifics and evolving global economic conditions.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

itstitle

excerptsa

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://www.binance.info/ru-UA/register?ref=OMM3XK51

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.com/bg/register-person?ref=V2H9AFPY

The insights you’ve shared here have already had a positive impact on my work.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I appreciate your straightforward approach.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.info/en-NG/register-person?ref=YY80CKRN

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

從英超、西甲、德甲到中超,全球各大足球聯盟的livescore運用AI智能分析技術即時比分都在這裡。

My coder is trying to convince me to move to .net from PHP.

I have always disliked the idea because of

the expenses. But he’s tryiong none the less. I’ve been using WordPress on a number of websites

for about a year and am worried about switching to another platform.

I have heard excellent things about blogengine.net.

Is there a way I can import all my wordpress posts into it?

Any kind of help would be greatly appreciated!

Good day! I could have sworn I’ve been to this website before but after reading through some of the post I realized it’s new to me. Anyways, I’m definitely glad I found it and I’ll be bookmarking and checking back frequently!

Hi! I could have sworn I’ve been to this website before but after checking through some of the post I realized it’s new to me. Nonetheless, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

Hey! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be bookmarking and checking back often!

Hello! I could have sworn I’ve been to this website before but after checking through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back often!

Hey there! I could have sworn I’ve been to this site before but after reading through some of the post I realized it’s new to me. Anyhow, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

Hello! I could have sworn I’ve been to this website before but after checking through some of the post I realized it’s new to me. Anyways, I’m definitely glad I found it and I’ll be bookmarking and checking back frequently!

Good day! I could have sworn I’ve been to this website before but after reading through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be book-marking and checking back often!

Hello there! I could have sworn I’ve been to this website before but after reading through some of the post I realized it’s new to me. Anyhow, I’m definitely glad I found it and I’ll be bookmarking and checking back frequently!

Hey there! I just wanted to ask if you ever have any trouble with hackers? My last blog (wordpress) was hacked and I ended up losing months of hard work due to no backup. Do you have any solutions to stop hackers?

Right here is the right blog for anybody who would like to understand this topic. You know so much its almost tough to argue with you (not that I personally would want to…HaHa). You definitely put a new spin on a subject that has been written about for many years. Great stuff, just excellent!

Hey would you mind sharing which blog platform you’re working with? I’m looking to start my own blog in the near future but I’m having a difficult time deciding between BlogEngine/Wordpress/B2evolution and Drupal. The reason I ask is because your design and style seems different then most blogs and I’m looking for something completely unique. P.S Apologies for getting off-topic but I had to ask!

I could not resist commenting. Well written!

Asking questions are truly good thing if you are not understanding anything completely, but this post offers fastidious understanding even.

I seriously love your site.. Great colors & theme. Did you build this website yourself? Please reply back as I’m planning to create my very own website and would like to find out where you got this from or just what the theme is named. Many thanks!

Remarkable! Its really remarkable paragraph, I have got much clear idea on the topic of from this post.

This piece of writing provides clear idea for the new viewers of blogging, that truly how to do blogging.

Hi! I simply wish to offer you a huge thumbs up for your excellent info you’ve got right here on this post. I will be returning to your blog for more soon.

Hiya very nice site!! Man .. Beautiful .. Wonderful .. I’ll bookmark your website and take the feeds also? I am glad to search out so many helpful information here within the publish, we want develop extra strategies on this regard, thank you for sharing. . . . . .

You actually make it seem so easy with your presentation however I find this topic to be really one thing which I believe I would by no means understand. It seems too complex and very huge for me. I am looking ahead for your next put up, I’ll try to get the hold of it!

It is perfect time to make a few plans for the longer term and it’s time to be happy. I have read this post and if I could I desire to counsel you few interesting issues or advice. Perhaps you could write subsequent articles regarding this article. I wish to read even more issues approximately it!

My brother recommended I might like this blog. He was totally right. This post actually made my day. You cann’t consider just how much time I had spent for this info! Thanks!

My partner and I stumbled over here from a different web address and thought I should check things out. I like what I see so i am just following you. Look forward to looking over your web page yet again.

It’s going to be end of mine day, however before finish I am reading this fantastic post to improve my experience.

Your style is really unique in comparison to other people I have read stuff from. I appreciate you for posting when you’ve got the opportunity, Guess I will just bookmark this site.

Highly descriptive article, I liked that bit. Will there be a part 2?

Hi there, just changed into aware of your weblog via Google, and found that it is truly informative. I am going to be careful for brussels. I’ll be grateful in case you continue this in future. Numerous people will likely be benefited out of your writing. Cheers!

Oh my goodness! Impressive article dude! Many thanks, However I am going through issues with your RSS. I don’t know the reason why I can’t subscribe to it. Is there anybody else getting the same RSS issues? Anybody who knows the answer can you kindly respond? Thanks!!

Wow that was strange. I just wrote an incredibly long comment but after I clicked submit my comment didn’t show up. Grrrr… well I’m not writing all that over again. Anyways, just wanted to say superb blog!

Fantastic beat ! I wish to apprentice while you amend your web site, how can i subscribe for a weblog site? The account helped me a appropriate deal. I were a little bit familiar of this your broadcast offered vibrant transparent idea

Great blog! Is your theme custom made or did you download it from somewhere? A theme like yours with a few simple tweeks would really make my blog shine. Please let me know where you got your theme. Cheers

These are genuinely enormous ideas in concerning blogging. You have touched some fastidious points here. Any way keep up wrinting.

Hello there! I know this is somewhat off topic but I was wondering if you knew where I could find a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having problems finding one? Thanks a lot!

There is definately a lot to find out about this subject. I love all of the points you made.

I read this paragraph completely on the topic of the comparison of newest and previous technologies, it’s amazing article.

If you wish for to grow your know-how only keep visiting this web page and be updated with the latest news posted here.

I am regular visitor, how are you everybody? This article posted at this website is in fact nice.

I’m truly enjoying the design and layout of your site. It’s a very easy on the eyes which makes it much more enjoyable for me to come here and visit more often. Did you hire out a developer to create your theme? Great work!

Hello there, You have done an excellent job. I will definitely digg it and personally suggest to my friends. I’m sure they’ll be benefited from this website.

I like the valuable info you provide in your articles. I’ll bookmark your weblog and check again here frequently. I am quite certain I will learn plenty of new stuff right here! Best of luck for the next!

Hello There. I discovered your blog the use of msn. This is a really neatly written article. I will make sure to bookmark it and return to learn extra of your helpful information. Thank you for the post. I’ll certainly comeback.

No matter if some one searches for his necessary thing, so he/she wants to be available that in detail, thus that thing is maintained over here.

Do you have a spam issue on this website; I also am a blogger, and I was wondering your situation; many of us have developed some nice methods and we are looking to exchange techniques with other folks, why not shoot me an e-mail if interested.

Hmm it seems like your site ate my first comment (it was extremely long) so I guess I’ll just sum it up what I had written and say, I’m thoroughly enjoying your blog. I as well am an aspiring blog blogger but I’m still new to the whole thing. Do you have any tips and hints for rookie blog writers? I’d definitely appreciate it.

Definitely believe that which you stated. Your favorite reason seemed to be on the internet the easiest thing to be aware of. I say to you, I definitely get irked while people think about worries that they plainly do not know about. You managed to hit the nail upon the top and also defined out the whole thing without having side-effects , people can take a signal. Will probably be back to get more. Thanks

If you desire to grow your experience just keep visiting this web site and be updated with the hottest information posted here.

Hello there! This article couldn’t be written any better! Reading through this post reminds me of my previous roommate! He always kept talking about this. I’ll forward this article to him. Pretty sure he’ll have a great read. Many thanks for sharing!

Very shortly this web page will be famous among all blog viewers, due to it’s nice articles

Does your website have a contact page? I’m having a tough time locating it but, I’d like to send you an email. I’ve got some ideas for your blog you might be interested in hearing. Either way, great website and I look forward to seeing it grow over time.

If you want to improve your experience only keep visiting this web page and be updated with the most recent news posted here.

It’s really a great and useful piece of info. I am satisfied that you shared this useful info with us. Please keep us informed like this. Thank you for sharing.

Howdy! Quick question that’s entirely off topic. Do you know how to make your site mobile friendly? My website looks weird when browsing from my apple iphone. I’m trying to find a theme or plugin that might be able to correct this problem. If you have any recommendations, please share. With thanks!

certainly like your web-site however you have to check the spelling on quite a few of your posts. A number of them are rife with spelling problems and I find it very bothersome to tell the reality however I’ll certainly come back again.

Hi there, I discovered your website via Google while searching for a related matter, your website got here up, it seems great. I have bookmarked it in my google bookmarks

Youth football livescore, U20 and U17 World Cup matches covered live

combinadas apuestas deportivas

My page: basketball-wetten.com

It’s nearly impossible to find well-informed people about this topic, however, you seem like you know what you’re talking about! Thanks

I was able to find good advice from your articles.

Woah! I’m really digging the template/theme of this website. It’s simple, yet effective. A lot of times it’s challenging to get that “perfect balance” between user friendliness and appearance. I must say that you’ve done a very good job with this. In addition, the blog loads very fast for me on Chrome. Exceptional Blog!

I was very pleased to discover this website. I need to to thank you for ones time for this particularly wonderful read!! I definitely liked every part of it and i also have you book marked to check out new stuff in your website.

Very quickly this website will be famous amid all blogging and site-building users, due to it’s good content

I know this site presents quality based posts and other material, is there any other site which presents these kinds of things in quality?

Undeniably believe that which you said. Your favorite justification appeared to be on the web the easiest thing to be aware of. I say to you, I definitely get irked while people consider worries that they plainly don’t know about. You managed to hit the nail upon the top and defined out the whole thing without having side-effects , people could take a signal. Will likely be back to get more. Thanks

Interesting blog! Is your theme custom made or did you download it from somewhere?

A theme like yours with a few simple tweeks would really

make my blog shine. Please let me know where you got your design. Thanks a lot

Hello my friend! I want to say that this post is awesome, great written and include

approximately all significant infos. I would like to look more posts like this .

you are really a just right webmaster. The web site loading velocity is amazing.

It kind of feels that you’re doing any unique trick.

Also, The contents are masterpiece. you’ve performed a magnificent process on this matter!

These are really fantastic ideas in on the topic of blogging.

You have touched some pleasant factors here.

Any way keep up wrinting.

I’m really inspired together with your writing abilities and also with the structure to your weblog. Is that this a paid topic or did you modify it your self? Anyway stay up the nice quality writing, it is rare to see a great blog like this one today..

Pretty section of content. I just stumbled upon your weblog and in accession capital to assert that I acquire in fact enjoyed account your blog posts. Anyway I will be subscribing to your augment and even I achievement you access consistently fast.

juego de apuestas online (Luca)

final copa del rey

en las apuestas cuenta la prorroga

my web page: basketball-wetten.com

apuestas al mundial [cordoba.Adventista.es]

para ganar en la ruleta

app apuestas Carreras de caballos Sanlúcar

wo am besten beste app für wetten

besten sportwetten apps

My homepage – wetten basketball verlängerung (http://Btob.N-Marketing.net)

legale wettanbieter esc wetten deutschland

live wetten deutschland buchmacher

wett prognosen heute

My web page welcher wettanbieter hat den Besten bonus

professionelle wett-tipps heute

my web blog – Wetten deutschland spanien

online casino real money no deposit australia, grand dusae casino no deposit

bonus and best real money pokies australia with neosurf, or online gambling casino italiani non aams nz

how to win slot machines canada, top 50 casinos in usa and td australia visa debit gambling, or

united statesn poker tournament

My web site free bets no deposit no wager; Kassandra,

slots no wagering uk, free money online rivers casino app bonus –

Leticia, canada

and windsor casino in united states, or usa online casino lists

no deposit online pokies nz, native united statesn casino issues and free casino usa bonus no deposit, or top 20 online casinos usa no deposit

my website – Goplayslots.Net

Hi to all, how is all, I think every one is getting

more from this web site, and your views are nice in support

of new users.

Here is my web site; mini blackjack table

I am really grateful to the holder of this site who has shared this great paragraph at at this place.

my web site :: how Much Does hard Rock casino pay

are the top online pokies and casinos in new zealand right now, gambling northeast

usa and free spins new usa, or mobile swtor casino prize vendor;

Harley,

no deposit bonus usa

Key passes, chance creation statistics for playmakers tracked

new no deposit casino canada, slots ironman lausaarote and casino sarnia ontario australia,

or registration bonus casino usa

Also visit my webpage – Can I Invest In Casinos

new blackjack live online real money; Helen, usa casino, united kingdom gambling

revenue and td australia visa debit gambling, or gambling operating licence uk

Get instant livescore updates for Premier League, La Liga, Serie A and Bundesliga matches today

barcelona vs sevilla Apuestas elecciones venezuela

foros de Que Es Doble Oportunidad En Las Apuestas; Transtuts.Com.Br, deportivas

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I like the helpful information you provide in your articles.

I’ll bookmark your blog and check again here regularly.

I’m quite certain I’ll learn lots of new stuff

right here! Best of luck iconnect casino app for android (Leila)

the next!

Hi there, I discovered your blog by means of Google even as searching for a similar topic, your website came up, it appears to be like great. I’ve bookmarked it in my google bookmarks

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

uk casino no deposit bonus no wagering, on line casino canada and ept poker chips

in usa, or potawatami casino milwausaee wi

Here is my web site – goplayslots.net

regulation of gambling in canada, online poker casino real money in usa and how many pokies are in united

states, or casino united states stock

Visit my web site :: goplayslots.Net

new online canadian casino, free real online pokies united states and yukon gold casino, or new zealandn online pokies min $5 deposit

my blog; statistics about gambling revenue

pokies return rate canada, online slots casino australia and online slot casino uk,

or $10 deposit online two rivers casino davenport wa –

Tyrone – australia

top online pokies and casinos united states pokies, spin usa casino and bingo united

states no deposit bonus, or canadian online gambling bill (Pauline) casino slots

real money canada

bet365 united kingdom martingale betting system in roulette (Agueda)

layout, united kingdom online casino real money free bonus

and 500 poker chips united kingdom, or online casino bc australia

Hmm is anyone else having problems with the pictures on this blog loading?

I’m trying to figure out if its a problem on my end or if it’s the gardens casino players Card blog.

Any feedback would be greatly appreciated.

I simply could not go away your web site before

suggesting that I extremely enjoyed the usual information an individual supply in your

guests? Is gonna be again continuously to check up on new posts

Feel free to surf to my web blog Ruidoso Casino

slots no wagering uk, online review casino royale 4k uk top 10 and how to make money online without paying

anything usa, or tax on gambling canada

poker sites australia, top 20 online how many casinos around

the world – Maryjo – uk no deposit and td

australia visa debit gambling, or usa online casinos gambling

casino in phuket, in casino way (Angelica) in usa

and free online gambling united states, or united

statesn online casino minimum deposit $10

apuestas osasuna barcelona (https://Rivatrading.de) grupos eurocopa

Appreciating the persistence you put into your

blog and detailed information you offer. It’s good to

come across a blog every once what is turnover in gambling a while that isn’t the

same outdated rehashed information. Wonderful read!

I’ve saved your site and I’m including your RSS feeds to my Google account.

free chip no deposit bonus codes 2021 canada, win real

money online instantly usa and hausaos dojo slot online real money

no deposit bonus, or no deposit bonus australian best Online Casino provider casino

5$ deposit casino canada, best online casino australia no deposit bonus and no deposit online canadian casinos, or casino cornwall ontario united

kingdom

Also visit my web page :: gambling suicidal behaviour – Geraldine

–

united kingdom online casino minimum deposit dollar 10,

party casino united states and usa online casino for usa players, or casino in milwausaee wi

Also visit my page :: can you gamble if your on disability – Santiago –

casino brisbane united states, gambling stocks united states and top 100 usa casino sites, or free

palace casino host (Denis) money

united states

casino uk pay by phone bill, united statesn casino

online and 100 no deposit bonus codes 2021 canada, or usa real

money slots no deposit bonus

my web page; is today a good day for pisces to gamble

(http://www.uncle-van.at)

gambling statistics uk, united statesn online casino

legal and united statesn casinos no deposit bonus,

or best wager Beat casino review sign up offers uk

gambling costs in australia, legitimate online pokies australia and online space

lilly casino promo code (Tonja) real money canada,

or minimum deposit 1 pound casino usa

I really like your blog.. very nice colors & theme. Did you make this website yourself or did you hire someone to do it for you? Plz respond as I’m looking to create my own blog and would like to find out where u got this from. cheers

wetten gutschein Ohne einzahlung deutschland

Hi to every , as I am really keen of reading this website’s post to be updated on a regular basis. It contains nice stuff.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.info/register?ref=IHJUI7TF

sportwette Basketball Wetten tipps nba

online wetten schweiz legal

Here is my web-site; Wett Tipps Kostenlos

wettseiten ohne oasis

my web site :: Sportwetten öSterreich Steuern

eugh sportwetten

Also visit my page … basketball live wetten strategie

wette quote berechnen

Also visit my site Buchmacher münchen

sportwetten selbst anbieten

Have a look at my web page :: wette sport (Samira)

wetten dass heute

Stop by my web page :: Dfb Pokal wettquoten

bild wett tipps

My website – wettanbieter deutschland ohne oasis (Esmeralda)

gratis wetten ohne einzahlung geizkragen

Here is my site – Buchmacher angebote – digital-Fashion.Online,

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for the good writeup. It in fact was a amusement account it. Look advanced to more added agreeable from you! By the way, how can we communicate?

Hello, I think your web site might be having internet browser compatibility issues. Whenever I look at your blog in Safari, it looks fine however, when opening in I.E., it’s got some overlapping issues. I merely wanted to give you a quick heads up! Apart from that, excellent website!

海外华人必备的yifan平台,提供最新高清电影、电视剧,无广告观看体验。

Sportwetten strategie Mathematik beste anbieter

Australian online casino real money – fast payouts and big bonuses

neue wettseiten

Also visit my web page … alle wettanbieter deutschland (blog.cosmopair.Com)

sportwetten deutschland

My web-site app wetten mit freunden

sportwetten apps

Here is my blog post; wettquoten frankreich deutschland (Carl)

wett tipps-heute tipp

ai erfahrungen

sportwetten schweiz verboten

Here is my page – wettbüro quoten (Melisa)

no deposit bonus sportwetten profi tipps

paysafecard wettanbieter

Here is my web-site Wetten Quote ErkläRung

wettformat gratiswette

Also visit my web-site: bonus code wetten

sicher wetten online österreich

die besten wetten

Here is my website :: Sportwetten Tipps Facebook (https://Tesouromodaintima.Com.Br/Racebets-Welcome-Offer/)

wettanbieter neu

Have a look at my site – sportwetten bonus Freispielen (https://Lalicorne-Nernier.com/2025/10/07/Wetten-bundesliga-spieltag/)

sportwetten mit bonus

My homepage … Online-Wetten (https://Www.Campionatocrawleritalia.It/)

Great weblog here! Additionally your website a lot up very fast! What host are you the use of? Can I am getting your associate hyperlink in your host? I want my website loaded up as fast as yours lol

new zealandn pm blackjack, 888 poker withdrawal united states and online casino canada roulette, or bingo no deposit bonus win real money

united states

My webpage … odds of craps rolls, newsletter.eta2U.Ro,